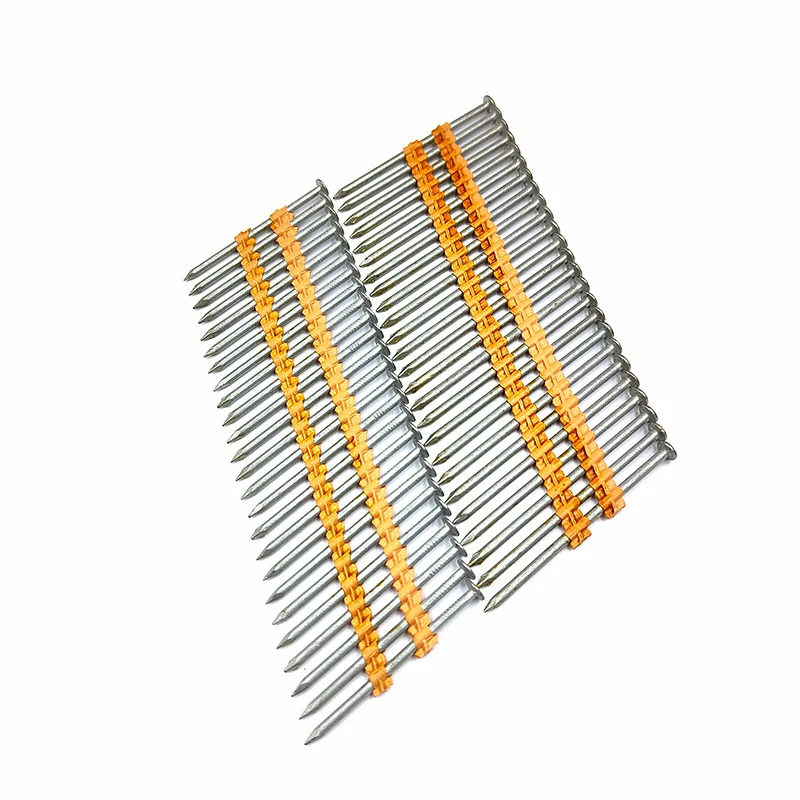

Plastic collated framing nails are a type of nail that is commonly used in construction and carpentry projects.

Here are some key features of plastic collated framing nails:

Collation: Plastic collation makes these nails easier to handle and load into a nail gun, which can save time and increase productivity. The plastic collation also helps to prevent jams and misfires, which can be a common issue with other types of framing nails.

Material: Plastic collated framing nails are made from high-quality steel, which makes them strong and durable. The steel is also coated with a layer of corrosion-resistant material to protect the nails from rust and corrosion.

Point: The point of plastic collated framing nails is designed to penetrate wood easily and without splitting the wood. This feature ensures that the nails can be driven in quickly and efficiently, with minimal damage to the wood.

Shank: The shank of plastic collated framing nails is designed to provide a secure hold in the wood, which helps to prevent the nails from pulling out over time. The shank is also designed to be smooth, which reduces friction and allows the nails to be driven in more easily.

Size: Plastic collated framing nails are available in a range of sizes to suit different applications. This allows users to choose the right size of nail for their specific project.

Compatibility: Plastic collated framing nails are compatible with a wide range of nail guns, making them a versatile option for contractors and DIY enthusiasts.

Overall, plastic collated framing nails are a practical and efficient solution for framing applications. By choosing nails that are collated using plastic, made from high-quality steel, plastic collated framing nails have an effective point and shank, and come in a range of sizes, users can ensure that their framing projects are completed quickly and effectively, with minimal damage to the wood.

Choosing the right size of plastic collated framing nail is important to ensure that the nail provides a secure hold and minimizes the risk of damage to the wood.

Here are some tips on how to choose the right size of nail for your project:

Consider the thickness of the wood: The thickness of the wood that you will be nailing into will determine the length of the nail that you need. As a general rule, the nail should be at least three times the thickness of the wood.

Consider the type of wood: Different types of wood have different densities and hardness levels, which can affect the size of the nail needed. Harder woods may require longer or thicker nails to provide a secure hold.

Consider the application: The application of the nail will also determine the size needed. For example, if you are nailing together two-by-fours for framing, you may need a longer nail than if you are attaching trim to a wall.

Consult a nail size chart: Many manufacturers provide nail size charts that can help you choose the right size of nail for your project. These charts typically list the recommended nail length based on the thickness of the wood and the type of application.

Test the nail size: Before starting your project, test the size of the nail by driving it into a scrap piece of wood. This will help you determine if the nail provides a secure hold and if it causes any damage to the wood.

By considering these factors and consulting a nail size chart, you can choose the right size of plastic collated framing nail for your project. This will help to ensure that the nail provides a secure hold and minimizes the risk of damage to the wood.